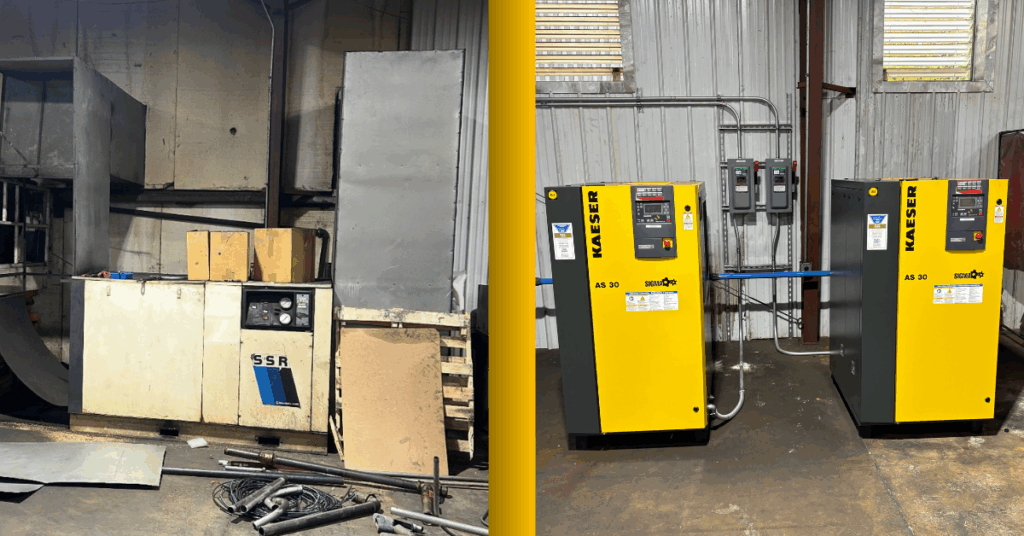

Out With the Old: A Central Michigan Tool & Die Shop Upgrades

When a tool & die shop in Central Michigan reached out about issues with their aging air compressor, they were experiencing the same challenge many manufacturers face: an outdated system that couldn’t keep up with production demands, and posed a real risk of costly downtime. The Challenge Their existing compressor was no longer delivering the reliability and efficiency they needed. With a busy production schedule and tight delivery timelines, even a brief interruption in compressed air availability could mean lost productivity and unexpected expense. Our Solution: A Dual-Compressor System After evaluating their application, usage, and capacity needs, our team […]

Stop Renting Your Nitrogen: How On-Site Generation Puts You Back in Control

You work hard to keep your operation efficient, safe, and profitable. However, if your business relies on nitrogen, whether for food packaging, laser cutting, electronics, or chemical processes, there’s a good chance you’re paying more than you should. Most companies still depend on delivered nitrogen because it’s what they’ve always done. However, this more “traditional” way of operating is quietly draining budgets and putting productivity at risk. You might be feeling the pressure of: – Never-ending delivery and rental fees – Rising transportation and fuel surcharges – Safety risks from handling and storing cylinders – Wasted gas returned unused […]

Why Kaeser Air Compressors Lead the Industry in Efficiency and Durability

When it comes to industrial air compressors, businesses can’t afford unnecessary downtime or wasted energy—reliability and efficiency are critical for productivity. That’s why Kaeser air compressors are trusted by leading manufacturers across Michigan and the globe, and why Air Components has proudly distributed Kaeser products since the mid-80s. The Power of Kaeser Air Compressors Kaeser air compressors are engineered to deliver consistent, high-quality compressed air for demanding industries such as automotive, food processing, manufacturing, and construction. Designed for continuous operation and heavy-duty environments, Kaeser’s industrial compressors are built with robust components, precision engineering, and an emphasis on long service […]

Take Advantage of 100% Bonus Depreciation on Compressed Air Equipment

Big tax breaks are back, and it could be the perfect time to invest in your compressed air system. What Changed? With the passage of the “One Big Beautiful Bill Act” (OBBBA, House Bill: Sec. 70301), businesses can once again take advantage of 100% bonus depreciation for qualified property purchased after January 19, 2025. This means you can deduct the full cost of eligible machinery, equipment, and systems in the year you buy them, rather than spreading the deduction out over time. Why This Matters Bigger Upfront Savings: Deduct the full cost right away. Better ROI: Larger purchases, such […]

How to Deal with Emergency Air Compressor Breakdowns and Repairs

Air compressors are essential in various industries, from manufacturing and construction to healthcare and automotive services. These machines power critical tools and processes, making their reliability vital for smooth operations. Unexpected air compressor breakdowns can disrupt productivity, leading to costly downtime and potential delays. This blog will explore common causes of air compressor breakdowns, how to prepare for emergencies, immediate actions to take during a breakdown, troubleshooting tips, and strategies to prevent future issues. Understanding Common Causes of Air Compressor Breakdowns Typical Issues Leading to Breakdowns: Air compressors can fail due to various reasons, many of which are preventable […]

The Importance of Regular Air Compressor Services and Inspections

Maintaining the optimal performance and efficiency of air compressors is crucial for any business that relies on these vital machines. Regular air compressor services and inspections play a significant role in ensuring the longevity and reliability of the equipment. This blog will explore the benefits of regular maintenance, key components of air compressor upkeep, common issues detected during inspections, the role of professional maintenance services, and some DIY maintenance tips. The Benefits of Regular Air Compressor Services and Inspections Enhanced performance and efficiency: Regular maintenance ensures that all parts of the air compressor are functioning correctly, leading to improved […]

What to Look for in a Quality Air Compressor Repair Service

Air Compressor Repair Services Expertise Choosing a quality air compressor repair service is crucial for maintaining the longevity and performance of your equipment. A reliable repair service can significantly impact the efficiency and lifespan of your air compressor, preventing costly downtime and ensuring consistent operation. Here’s what you need to consider when selecting a repair service to meet your needs. Experience in Air Compressor Repairs The first factor to consider is the experience of the repair service in handling air compressors. Look for a service provider with a proven track record of repairing various air compressor models and brands. […]

Compressed Air Equipment Maintenance 101

Understanding Compressed Air Systems Compressed air equipment is essential for a wide range of industrial and commercial applications. Proper compressed air equipment maintenance is not just a matter of keeping your equipment running; it’s crucial for ensuring longevity and efficiency. Regular maintenance helps prevent breakdowns, reduces energy costs, and prolongs the life of your equipment. Compressed air systems are complex, consisting of various components that work together to generate and deliver compressed air. Key Components Include Air Compressor: The core unit that compresses air. Air Dryer: Removes moisture from the compressed air. Air Filters: Clean the air before it […]

Why Compressed Air Equipment is the Backbone of Many Industries

The Versatility of Compressed Air Compressed air equipment is an essential component of various industries, playing a crucial role in powering many applications. This blog post will explore the importance of compressed air in different sectors and discuss its advantages over other power sources. Compressed air is used as a power source for various pneumatic tools, offering a safe and efficient alternative to traditional power tools. Additionally, compressed air is clean, easy to control, and adaptable, making it suitable for a wide range of tasks. Manufacturing Industry: Pneumatic tools such as drills, grinders, and impact wrenches are powered by […]

Advantages of Compressed Air Equipment in Industrial Operations

The Advantages of Compressed Air in Industrial Operations One of the key advantages of compressed air is its energy efficiency and cost-effectiveness. Compared to other energy sources, compressed air systems offer higher energy efficiency, reducing operational costs for businesses. Additionally, compressed air can be easily stored and transported, making it versatile in a wide range of industrial applications such as powering pneumatic tools, controlling machinery, and facilitating automation processes. Furthermore, compressed air is environmentally sustainable, creating a reduced carbon footprint compared to traditional energy sources. Industries can contribute to a cleaner and greener environment by utilizing compressed air equipment. […]